Our ordering process for custom profiles consists of six steps:

The manufacture of custom profiles begins by listening to your needs.

Our account managers collect:

- your CAD drawings (.dxf, .dwg),

- your reference samples,

- your technical constraints (material, tolerances, Shore hardness),

- the profile’s environment,

- the standards required for your specific field,

- your specific finishing requirements (welding, marking, cutting, drilling, adhesive, etc.),

- the volumes required for your request.

This step allows us to establish clear specifications in order to develop the profile best suited to your application.

Upon receipt of your project, our technical sales team analyses your request and, if necessary, asks our tooling manufacturing experts to carry out an in-depth technical feasibility analysis. This key step allows us to assess the viability of your request, taking into account material constraints, technical specifications and applicable standards.

Once feasibility has been confirmed, our sales team will draw up a detailed, transparent and competitive quotation. This document will include all your criteria: production volumes, deadlines and specific requirements (quality, finishes, materials, etc.).

Our collaborative approach between the design office and the sales department ensures a rapid, accurate and personalised response, supporting you from concept to completion.

Once the quote has been accepted, your order is validated by our administrative department and incorporated into our tooling and production planning.

We check every detail to ensure that the work is carried out in line with your expectations, then start production as soon as possible.

This prototyping stage involves our technical teams and our in-house tooling workshop:

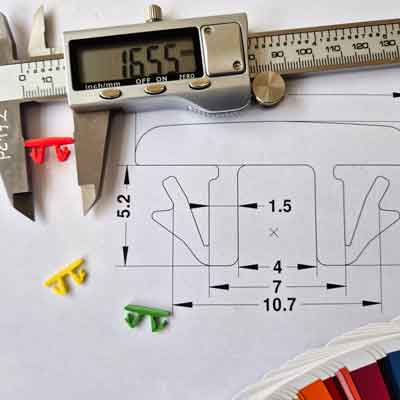

- CAD design of the profile.

- In-house manufacture of the extrusion die (CNC machining, electroerosion cutting).

- In-line die testing carried out by our extrusion technicians, withverification of the profile obtained.

Average lead time:

- 10 days for a single-material profile,

- 20 days for a co-extruded profile (multiple materials or colours).

We can also commit to shorter lead times.

Our quality department carefully checks that it meets your requirements: dimensions, mechanical strength, surface finish, colour and other technical criteria.

This is a key step in ensuring that the result meets your expectations before production begins.

Your prototype is sent to you by express delivery for final approval under your conditions of use.

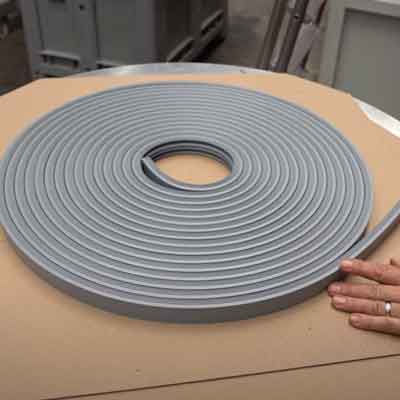

Mass production of your elastomer profiles begins once you have given your approval:

- our extrusion technicians adjust the machines to ensure a stable process,

- our quality department carries out rigorous checks at every stage.

The TPE profiles extrusion process involves:

- The introduction of Prodene granules into the hopper,

- Melting in the heated cylinder by the screw conveyor,

- Passage under pressure through the die,

- Cooling (under water in a closed circuit),

- Cutting or winding as required.

Our TPE profiles can be single or co-extruded, multi-material or multi-coloured.

Why choose Prodex for your custom extruded profiles?

- Recognised expertise in elastomer extrusion for over 27 years

- Integrated tooling workshop for optimal responsiveness

- Quality guaranteed by our control department

- Complete process: from design to mass production.