Definition

The Shore hardness scale measures the hardness of elastomers (rubber, EPDM, PVC, Silicones, TPE, TPV, SEBS…), some plastics, leathers, wood…

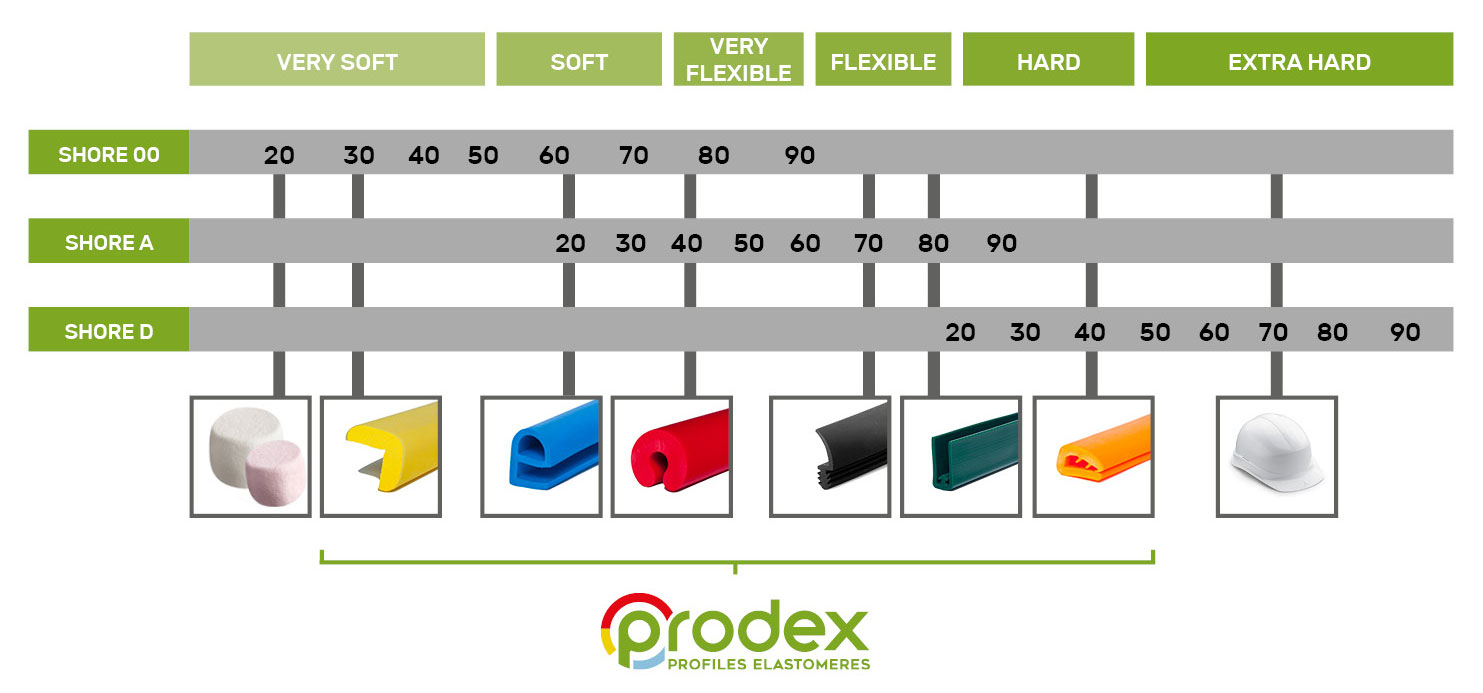

For our range of materials, we use scales A and D:

- Shore A (for soft materials)

- Shore D (for hard materials)

Measurement conditions and different hardness scales

The measuring tool is called durometer.

The tip of the penetrating rod is different on Shore A and Shore D durometers.

To measure the hardness correctly, the sample must have a minimum thickness of 6 mm (we recommend 10 mm).

The profile surface must be flat.

For an extruded profile, the measurement must be taken on the section (not on the external surfaces): therefore it is necessary to cut the profile to have a regular slice.

The measurement must be made at ambiant temperature on a hard flat surface.

Measurement tolerances

Tolerances are usually +/- 5 shore, it allows to take into account the vulnerability of the measurement method and the manufacturing process.