Prodene materials : a unique experience

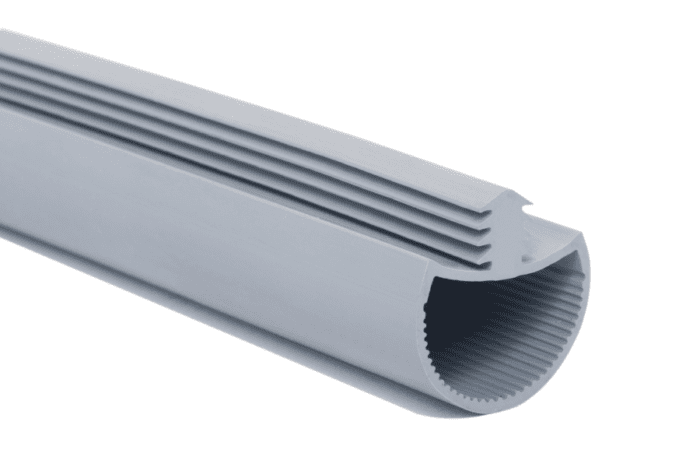

Prodex is an extruder for profiles made of thermoplastic rubber elastomers (TPE, TPV, TPS) type SEBS, PP-EPDM (Santoprene) in a hardness range from 15 shore A to 45 shore D.

All our products are 100% recyclable (except those that have been adhered).

Prodene Elastomeric Thermoplastic Rubbers can be used from -40°C to +100°C, with excellent resistance to UV and ozone, acids and bases, and washing agents.

A complete response for normative needs

Our Prodene materials all comply with REACH RoHS regulations. They can meet CE or FDA food contact regulations, CSTB & RAL-GZ building standards, fire and smoke standards: EN 13501 (building), EN 45545 (transport), UL94Vo (electrical equipment), and comply with European Directives EU 2011/65/CE (RoHS2) and 2000/53 CE (end-of-life vehicle).

Ability to meet your colour needs

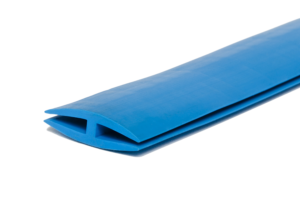

Prodene thermoplastic elastomeric rubbers can be coloured according to a list of more than 60 standard colours or according to the customer’s request (RAL, PANTONE, etc…).

The colours can be matt, translucent, metallic, fluorescent or phosphorescent.

An answer dedicated to your specific needs

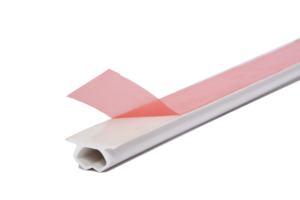

Thanks to our workshop of small series, we realize your profile to measure from 25 meters in mono-material.

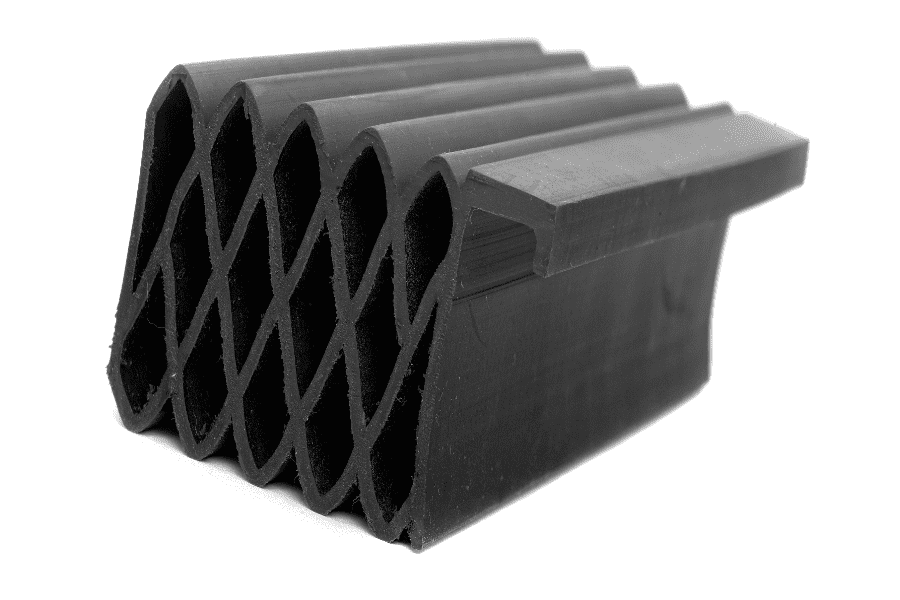

The profile can be co-extruded to offer multi-hardness or multi-colour seals, e.g. 2 or 3 different materials, 2 or 3 colours, different hardnesses or compact/foam combinations.

Several foam qualities (black, white or coloured) are available as standard in different densities.

The in-house production of the dies and our extrusion machine park enable us to guarantee very short manufacturing lead times.

A small energy footprint

TPE is the material that consumes the least amount of energy to make gaskets.

With a 20% lower density compared to other elastomers, TPE reduces energy consumption.

With TPE you choose :

- less energy to supply the raw material

less energy to produce and extrude

less energy to deliver your profiles

less weight for your projects